NEKONOTE Manufacturing

The era where anything will sell if it is cheap enough has past, however, that is not to say that luxury goods are more preferred.

What type of goods are preferred in todays era ? We believe it is the practical goods that feel just that bit special compared to the rest.

The Origins

NEKONOTE started in 2007 after clients wishing to buy leather from Hashimoto Industry requested a place to receive assistance with their “making” process demands.

The demands were too small to take to established makers and too big to handle by themselves. To answer the demands of these clients while continuing its work as a leather and leather cord producer, and utilising existing knowledge and skills the “Making” business was started.

After that, several staff with experience in mass production joined, dedicated sewing machines where purchased and fully fledged “Manufacturing” started

Currently there are 3 dedicated staff members managing each process consistently from planning to production.

The Most Important Things

-

01. Communication

In NEKONOTE, in addition to information about the item and its shape it is important to decide when, where, to whom and how to sell.

Depending on the target audience, sales method, and the number of days until sale, the material to be used and the end details should be changed.During the initial meetings it is important to grow the product by sometimes discussing different unrelated topics. There needs to be a harmony between the Seller, Designer and Maker all brainstorming to begin the “making” process.

-

02. Selecting appropriate Material

The look and feel of the product depends greatly on the material used. At NEKONOTE, we leverage the unique experiences from Hashimoto Leather Industry to propose materials suitable for the look and feel of the client’s request.

Of course, the client does not need to know anything about leather. At NEKONOTE, we have gathered an experienced team of members who can discuss all things related to leather. Feel free to ask anything to our experienced staff.

-

03. Conscientious work

NEKONOTE provides a consistent one stop shop approach from leather selection all the way to shipping the final product.-

** Selection of leather **

From the same cut of leather, choose the size and condition that best fits the product.

-

** Cutting **

The number of cuts you can get from the same piece of leather greatly changes the price of the finished product. The experience of the leather artisan plays a big role here.

-

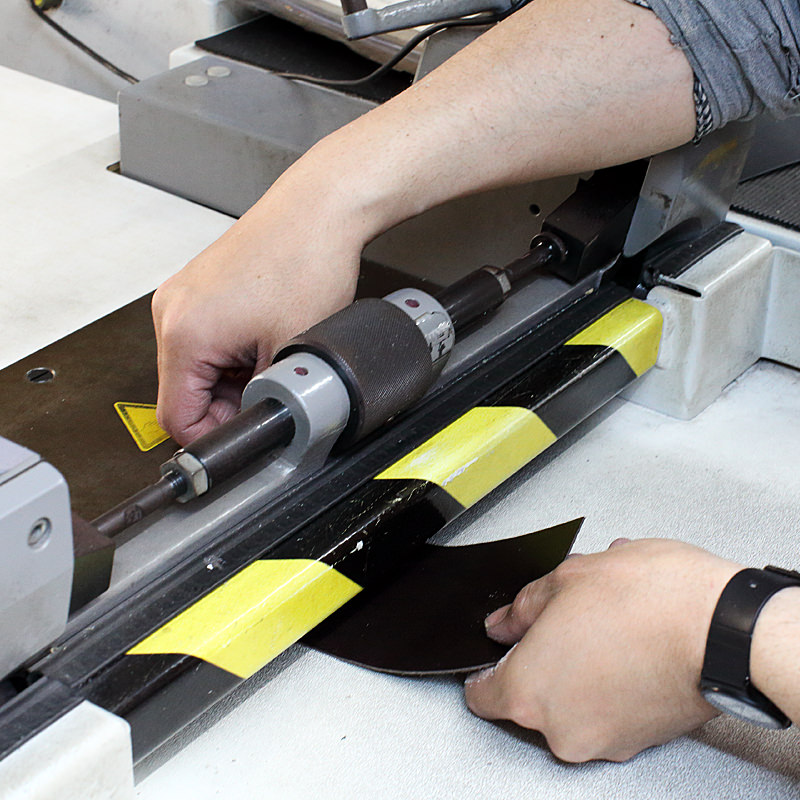

** Splitting **

In order to make the facade various parts of the leather product are made to different thicknesses. The thickness of the leather is adjusted using a high quality leather splitting machine, one that is often used in making leather straps.

-

** Thinning **

Because the overlapping portion of leather products becomes thicker, the thickness of the leather is partially adjusted, making the facade and the sewing process easier.

-

** Stamping **

Using the press machine, part are pressed with a stamp. You can specify boldness or thinness of the stamping and the colour of the embolding foil.

-

** Cutting Process of parts **

Make parts by aligning the cut edges then fixing them together with special tools. Items are finished by colouring and sealing in a way suitable for each part.

-

** Slitter **

For slender objects such as belts and wound leather, slitters are used to cut the leather just like pasta.

-

** Sewing **

Three different sewing machines are utilised depending on the type of good and parts to be sewn. Partial hand sewing is also done.

-

** Cut processing **

Various kinds of colouring, polishing, sealing and so on is performed on the leather cuts. It may take more time than just sewing, but it is an important part of the facade of the product, so should not be underestimated.

-

** Inspection **

It is ensured that at least three sets of eyes are engaged during the sewing and at other stages, all work is performed under close scrutiny .

-

** Packing **

Delivery will be done based on client’s choice, such as bagging or boxing. Packing will be completed for each product individually and with close scrutiny.

-

** Delivery **

If there are any issues with the delivered items, please contact us at any time. Even the smallest things will be responded to.

-

-

04. Fair price

Material Costs and Processing Fees. These are the two main areas where costs are incurred in ”making” process.-

** Material Cost **

In the case of leather, this is determined by how much of the product can be made from the leather of one animal. If no scratches are allowed, it can be very expensive, if some marks, injuries or stains can be allowed then savings are possible. In addition, the utilisation of end leather can reduce material costs with leather manufacturing. If the original cut material is large, it is recommended to make many smaller cuts from the same piece.

-

** Processing Fee **

This is the total time taken from material arrangement to completion, converted to money. (Arrangement Time + Production Time) ÷ Production Number, this is the time it takes to complete a single item. Since the Arrangement Time does not change based on Production Number, if the number is small, the Processing Fee will rise. Also, as good quality items take extra time, this will be reflected in the Processing Fee.

-

NEKONOTE

At NEKONOTE, we try to balance quality and price. If you are not 100% satisfied with your quotation, please feel free to discuss with us a mutually agreeable level of quality and price.