Company : Ecology

Improvements in the safety of leather

Our company is committed above and beyond just handling leather to developing the leather industry into a sustainable one that contributes in an environmentally friendly way offering materials that are safe for human use.

Zeomic Ag⁺ Leather Coating

This chemical was developed by mixing “Zeomic®,” the first inorganic antibacterial agent for genuine leather that was developed using the antibacterial activity of the silver ion Ag⁺, and a top coating agent for leather.

Characteristics of Zeomic®

It keeps leather products clean by inhibiting the propagation of various bacteria on leather surfaces. Zeomic, which is used in the Ag⁺ leather top coating agent, is a silver-based inorganic antibacterial agent that satisfies various needs related to preventing the spread of bacteria.

*Zeomic® is the world’s first silver-based inorganic antibacterial agent that Sinanen Zeomic commercialized in 1984. It is superior to organic antibacterial agents in many aspects, such as safety, durability, and heat tolerance, and has been highly received not only in Japan but around the world. “ZeomicⓇ is a registered trademark of Sinanen Zeomic Co., Ltd.”

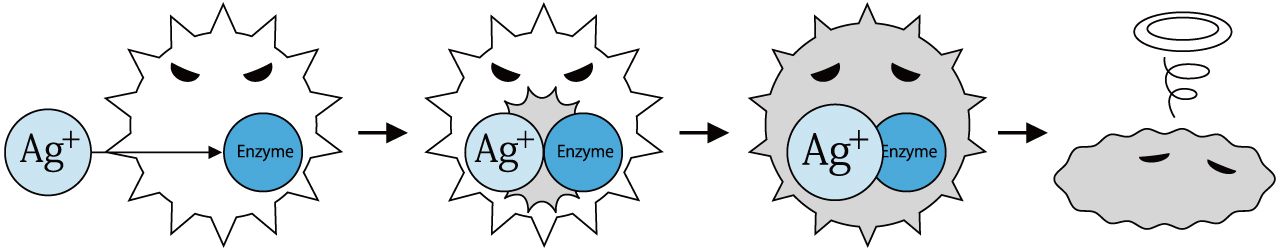

Antibacterial Mechanism of Zeomic

Even if bacteria adhere to leather products to which Zeomic Ag⁺ Leather Coating has been applied, they can only live for a certain amount of time or can no longer propagate. As a result, their propagation is inhibited by making the surface difficult for the bacteria to live in, instead of by killing or decreasing them.

①The silver ions in Zeomic are absorbed on the surface of microorganisms and ingested into the bacterial cell through active transport.

②The silver ions react to various metabolic enzymes inside the microorganism.

③They block the movement of various metabolic enzymes and inhibit propagation of the microorganism.

Precautions

・Ag⁺ Leather Coating maintains maintains the inherent characteristics of leather.

・Depending on the color of the leather, it may give it a hazy look.

・The Zeomic Ag tag certifies that leather that has been processed with Zeomic Ag⁺ Leather Coating has been used.

・The antibacterial effects vary based on the frequency of use and the environment.

Improvements in Safety ( Eco Leather Development Initiative )

In recent years, environmental problems and the impact of harmful substances on the human body have been questioned in the manufacturing industry, Hashimoto Industry not only continues its effort to protect the environment,

we also believe that the development of Eco Leather is indispensable while incorporating materials that are safe for human use and incorporating environmentally friendly manufacturing methods.

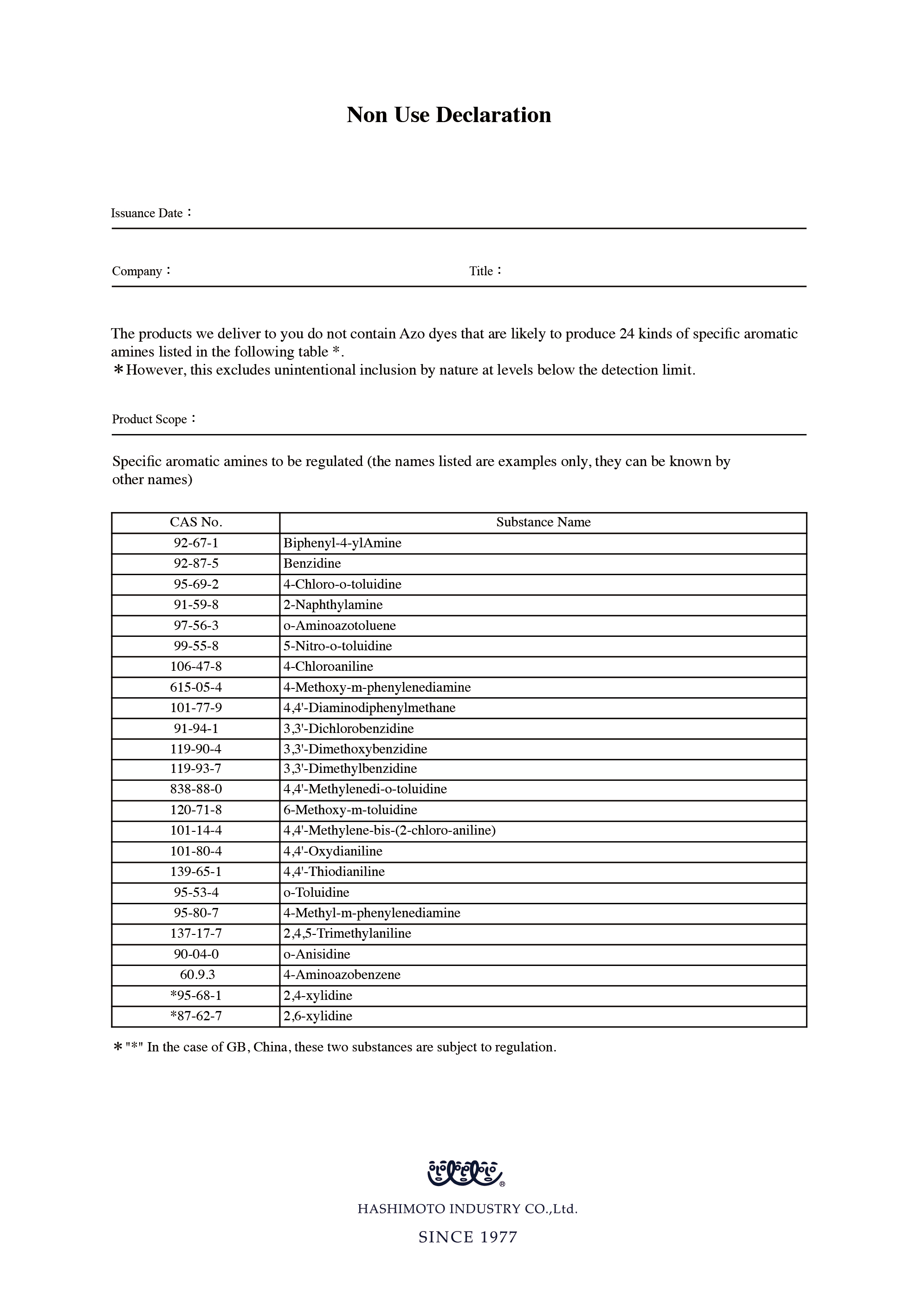

1) Declaration of non-use of “Azo Dye that produces specific Aromatic Amine"

Materials handled by our company do not use “Azo Dye that produces specific Aromatic Amine” in compliance with regulated substances under the “Law Concerning Regulation of Household Goods Containing Hazardous Substances” that was added on April 1, 2016.

With the cooperation of each of our tanners we issue a “Non Use Declaration”.

About Azo Dye regulation

Azo Dyes themselves are very common dyes, and 60% of commonly distributed dyes are this category.

The above law does not tell the whole story of regulating all Azo Dyes, Only about 5% of dyes in this Azo Dye category produce bacteria and enzymes on the surface of the leather that is believed can create carcinogenic “specific Aromatic Amine”.

2) Non-use of lead based pigment in some materials.

Pigments used in the finishing process include inorganic pigments and organic pigments, some inorganic pigments like, orange, yellow and red, can contain lead.

These pigments are often used in the finishing process because they have better staining properties and are cheaper, however they often exceed the minimum safety standards.

In general any lead is harmful and we do not use lead based pigments.

3) Non-use of Surfactant in the tanning process (Number One only) ( NP Free )

In the finishing process of raw leather from animals, we use a surfactant to remove collagen fibres, hair, fat and the epidermis layer.

It is also often used to improve penetration during dyeing. There is no known effect on human use like lead, however, hazardous substances are generated at the time of disposal.

Currently, surfactant is not used in the our “Number One” materials.

In the future, we will continue our efforts to increase the used of NP Free materials from an environmental conservation standpoint.

4) Reuse of packing materials etc.

In consideration of the environmental impact caused by disposal, our company is trying to reuse where possible without discarding a variety of materials such as paper to be used for packing and single use core to bind leather. Since leather material is not cheap, some people who purchase our products may have mixed feelings about the slightly torn packaging papers, but we use these to be consciousness of the environment and hope that our customers understand. We would like to continue our efforts towards this kind of environment protection while ensuring that we do not damage the quality of the items purchased.

Inquiries about “Non Use Declaration"

Click Here for inquiries about “Non Use Declaration"

Contact Form